DRIVE SHAFT SOLID SPHERICAL BEARING REPLACED IN UNDER THREE HOURS WITH BOWMAN SPLIT ROLLER SN/SD/SAF

CLIENT CHALLENGE

When a well-known North American tugboat operator suffered a bearing failure that put a primary boat out of action during the fulfilment of a significant contract, the team needed a bearing delivered and installed as quickly as possible. Although time was of the essence, marine environments are demanding and corrosive, and the replacement drive shaft support bearing needed to offer the same or better performance compared to the one that failed.

Each of the tug’s propeller shafts were supported by SN housed solid spherical roller bearings which, like many solid bearings, were time consuming to remove and replace. Typically, this process takes up to three days with the removal of the propeller shaft as well as the surrounding ancillary equipment so that the damaged bearing can be withdrawn and completely and replaced.

For many vessels, this process would require access to a dry dock, which requires pre-planning and often lengthy wait times, dramatically impacting the duration and cost of downtime. Thankfully on this occasion, the tugboat had Z drives, eliminating the need to dry dock.

KEY PROJECT STATISTICS

- A well-known American tugboat operator suffered a bearing failure during the fulfilment of a significant contract

- Bowman reduced the bearing changeout time from three days to three hours

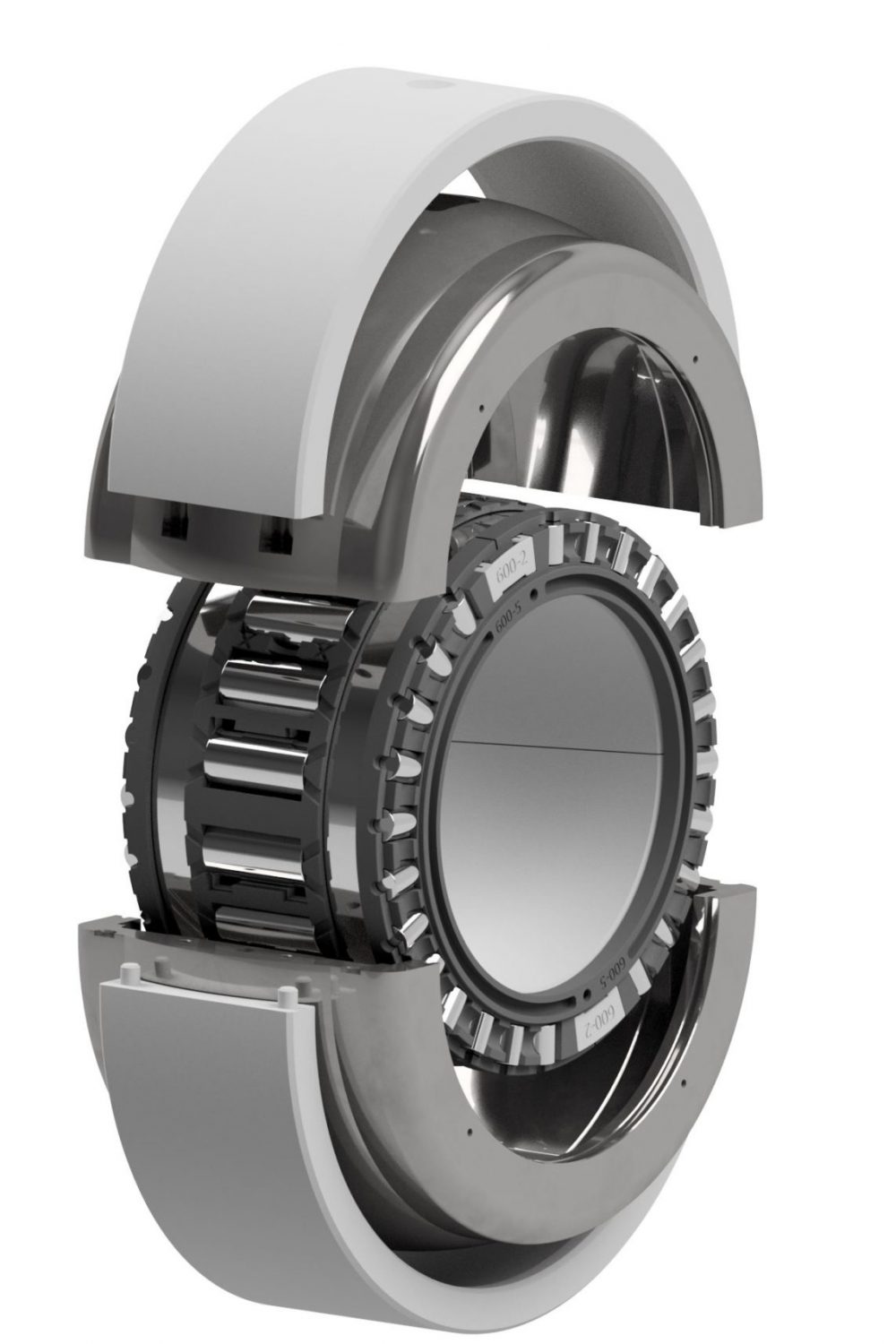

- A solid spherical bearing was replaced with an interchangeable split roller bearing

- Existing customer pedestal remained in-situ

- The contract was fulfilled without delay

- Cost savings were estimated at between

- $3,500 and $6,000

BEARING TECHNICAL DETAILS

- Shaft diameter: 125mm both fixed and expansion (free) bearings

- Installed into customer’s existing SNL528 housing

- Shaft speed: 1600rpm (max)

- Bearing replaced: 22228 spherical roller bearing with H3128 adaptor sleeve

BOWMAN SOLUTION

Upon discovering the bearing failure, the engineering team recalled a product they had seen at a recent workboat exhibition – the Bowman SN/SD/SAF split roller bearing.

Designed to replace equivalent solid spherical bearings, the Bowman SN/SD/SAF split roller bearing, delivers faster change out times and better radial and axial-load capacity.

Bowman reassured the tugboat engineers that they would be able to replace the failed solid spherical bearing in a fraction of the time expected and would benefit from a number of performance advantages over the existing SN housed solid spherical roller bearing, including increased radial and axial load carrying capabilities, higher shock load capability and increased permissible shaft misalignment.

Knowing that the new Bowman bearing would arrive on site within 48 hours, the maintenance team set to work, removing the SN pedestal cap and cutting away the solid spherical bearing. The new SN/SD/SAF Split Roller Bearing was then assembled radially around the shaft, into the existing SN pedestal in under three hours.

Discovering a worn shaft

During the bearing replacement, it was discovered that the seal to shaft contact area was badly damaged. The usual course of action in this instance would be to remove and repair the propeller shaft, creating even more downtime and delays to ongoing customer fulfilment.

Instead, Bowman supplied its patented extended triple labyrinth seal, that can quicky and easily be located on a non-worn part of the shaft. Eliminating the need for prop shaft removal, repair or replacement, Bowman’s extended seal lengthens the life of worn shafts, reducing maintenance costs and downtime thus putting vessels back into service quicker.

The customer was delighted with the cost and time savings achieved by switching specification from its usual solid spherical bearing to Bowman’s performance-engineered, dimensionally interchangeable SN/SD/SAF split roller bearing.

“Utilising our unique product development, it is possible to replace a high-load solid spherical bearing, with a split roller bearing to make bearing change-out faster. For this customer in particular, the Bowman SN/SD/SAF range of high-load capacity dimensionally interchangeable bearings got one of their primary working boats back on the water within hours instead of days, delivering substantial cost savings and upholding customer fulfilment.”

Matthew Simmons, Technical Manager, Bowman Split Bearings